TECHNICAL SUPPORT

부 메뉴

- Rupture Disc Introduction

- KOSHA Obligation Safety Certification

- Tolerance per Standard

- Selection Guide

- Selection Model

- Application of Rupture Disc

- Installation

- Rupture Disc Sizing

Quick Menu

현재 위치

Home > TECHNICAL SUPPORT > InstallationInstallation

We are making a company of trust with a unified heart.

Prevention of safety accidents by learning installation method in heart!

Please read carefully and be familiar with preparation stage (Rupture Disc Inspection and Holder Inspection), and installation methods to prevent safety accidents.

Holder Inspection Installation of

Rupture Disc

Preparation

Rupture Disc Inspection

lease take extra care when you hold the Disc and the Nameplate.

Check sheet at the edge of the disk and surface of the dome if there is any groove, scratch, or stains that can cause leakage or affect rupture pressure. Do not install damaged disc.

If damaged disc is installed, the disc can be ruptured earlier than scheduled and it may not function properly as a safety device.

Holder Inspection

-

Inspect both sides of the sheet to which Holder Disc will be assembled. Dust or small sands can damage the Rupture Disc.

Alien substances and damages can affect the operation of disc and it may damage disc or cause a leakage. Clean it as much as possible, and grind lightly before installation if there is a groove or damage on the surface of metal joints. - Size and grade of the Holder shall be consistent with size and grade of the Flange.

- Rupture Disc and Holder should not be processed or modified without authorization of FDC. Arbitral process or modification will nullify the warranty of the product.

Installation of Rupture Disc

- Rupture Disc can be installed vertically or horizontally.

- Rupture Disc shall be installed according to the direction of material flow.

- When handling a Rupture Disc, do not touch processed parts for pressure setting such as Dome molded part, Scored processed part, and Slit processed part. When you hold a Disc, be usred to use sheet at the edge of the disk so that it will not be damaged.

- Rupture Disc shall be installed together with a Holder. If there is damage on the Disc, it shall be installed no matter what damage it is. (However, it can be installed alone in some models.)

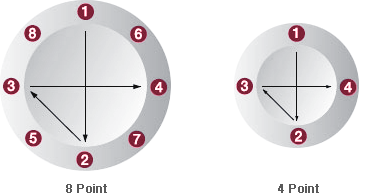

- The surface of both holders to which a Rupture Disc is assembled. It should be free from dust or damages. Bolt shall be tightened with the same symmetrical power according to the order shown in the following picture.

※ Note: Leakage can be prevented only when bolts are tightened with the same power following this order.

Republic of korea FDC Co., Ltd. TEL : +82(0)55-337-0852 FAX : +82(0)55-337-0858

Copyright(c) FDC Co., Ltd. All rights reserved. 어제 : 130 / 오늘 : 50 / 전체 : 238,596