Mandatory Safety Certification

임직원 모두 하나 된 마음으로 신뢰가 기본인 회사를 만들어 갑니다.

A system promoted to contribute to the prevention of industrial accidents by ensuring that products with fundamental safety and reliability can be manufactured, distributed, and used by attaching a certificate mark to products that meet or exceed safety certification standards in terms of the production of protective equipment and protective gear for hazardous machinery/equipment.

A rupture disc used to protect pressure vessels from overpressure or vacuum due to gas or vapor (However, this does not apply to the cases where it is used to release the pressure of liquid or when the set burst pressure is less than 0.1MPag.)

Rupture test conducted at the same temperature as the usage environment (room temperature rupture test)

A separate certificate of the same format is required if the specifications submitted at the time of the certification application differ

Mandatory use of certified products in all imported products

Occupational Safety and Health Act

Enforcement Decree of the Occupational Safety and Health Act

Enforcement Rule of the Occupational Safety and Health Act

Notice on mandatory safety certification standards for protective devices

Notification on the Reporting of Safety Certification and Voluntary Safety Confirmation

※ Violation: Imprisonment for up to 3 years or a fine of up to KRW 20,000

Burst test

Set Pressure |

Less than 0.3 MPag |

0.3 MPag or more |

|---|---|---|

Burst Pressure Tolerance |

±0.015 MPag |

±5% |

Leak Test

Category |

Pressure Holding Time |

|

|---|---|---|

Nominal Diameter of Rupture Disc (mm) |

50 or less |

1 minute |

Over 50 up to 100 |

2 minutes |

|

Over 100 |

3 minutes |

|

※ Leakage test performed at 90% of the set pressure

※ For Flat/Slotted Type, the leakage test is performed at 50% of the set pressure.

Classification by Structure

Dome-shaped rupture disc (C) |

Fragmented type (O) |

|---|---|

Composite Type (C) |

|

Scored/etched type or slit-type (S) |

|

Inverted dome-shaped rupture disc (R) |

Scored/etched type or shear-operating type (S) |

Blade type (K) |

|

Flat-type rupture disc (F) |

Replaceable graphite rupture disc (R) |

Monoblock graphite rupture disc (M) |

|

Slit-type rupture disc (S) |

|

Other Structures (X) |

Rupture discs manufactured according to manufacturer characteristics, other than the shapes above |

Classification by Nominal Diameter

Nominal Diameter Classification |

I |

II |

III |

IV |

V |

|---|---|---|---|---|---|

Nominal Diameter Range (mm) |

25 or less |

Over 25 up to 50 |

Over 50 up to 80 |

Over 80 up to 100 |

Over 100 |

Classification by Nominal Pressure

Nominal Pressure Classification |

1 |

2 |

5 |

10 |

21 |

22 |

|---|---|---|---|---|---|---|

Burst Pressure Range (MPag) |

1 or less |

Over 1 up to 3 |

Over 3 up to 5 |

Over 5 up to 10 |

Over 10 up to 21 |

Over 21 |

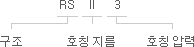

Marking of Types