Rupture Disc Sizing

임직원 모두 하나 된 마음으로 신뢰가 기본인 회사를 만들어 갑니다.

saturated steam |

NOTE) For pressures below 1500 psig, the above formula applies, and for dry saturated vapor pressures above 1500 psig and below 3200 psig, the value calculated by the above formula must be corrected by multiplying by the following factor.

|

|---|---|

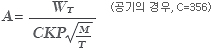

gas / air |

|

liquid |

|

| WT | Discharge Flow Rate | (lb/hr) |

|---|---|---|

| A | Actual Discharge Area in the Open State of the Rupture Disc | (in²) |

| P | Apply the larger value of ‘(Set Pressure x 1.10) + Atmospheric Pressure’ or ‘Set Pressure + 3 psia + Atmospheric Pressure’ | (psia) |

| Pd | Back Pressure (Pressure on the Discharge Side) | (psia) |

| M | Molecular Weight | |

| T | Absolute Temperature at Valve Inlet, °F + 460°F | (R) |

| C |

Constant for Gas or Vapor Based on Specific Heat Ratio

|

|

| K | Discharge Coefficient (Design Value: generally 0.62 for rupture discs; for actual measurement, measured value x 0.9, but must not exceed 0.8775) | |

| Z | Compressibility Factor Related to P and T (If no data available, Z = 1.0) | |

| W | Specific Weight of Liquid at Valve Inlet Conditions | (lb/ft³) |

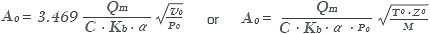

Gas / Vapor under Critical Flow |

For the homogenized wet steam of 90% or more dryness

|

|---|---|

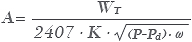

Gas / Vapor under Subcritical Flow |

|

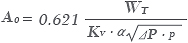

Liquid |

|

| A0 | Minimum Required Flow Cross-Sectional Area | (mm²) |

|---|---|---|

| Qm | Mass Flow Rate | (kg/h) |

| C |

Function of Isentropic Exponent k

|

|

| V0 | Specific Volume at Actual Discharge Pressure and Temperature | (m³/kg) |

| P0 | Discharge Pressure | (bar a) |

| α | Discharge Coefficient (generally 0.62 applied) | |

| T0 | Discharge Temperature | (K) |

| Z0 | Compressibility Factor at Actual Discharge Pressure and Temperature (if no data available, Z0 = 0.1) | |

| M | Molecular Weight | kg/kmol |

| x | Dryness Fraction of Wet Steam | |

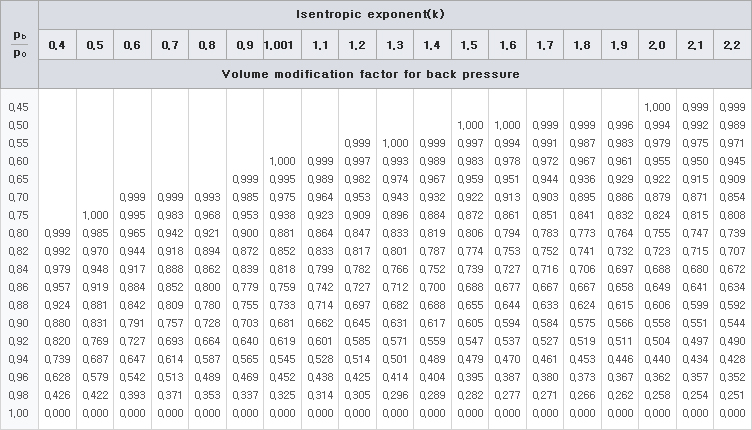

| Kb |

Correction Factor for Theoretical Capacity Reduction due to Back Pressure Increase under Subcritical Flow (Refer to Table 2 Capacity Correction Factor for Back Pressure) |

|

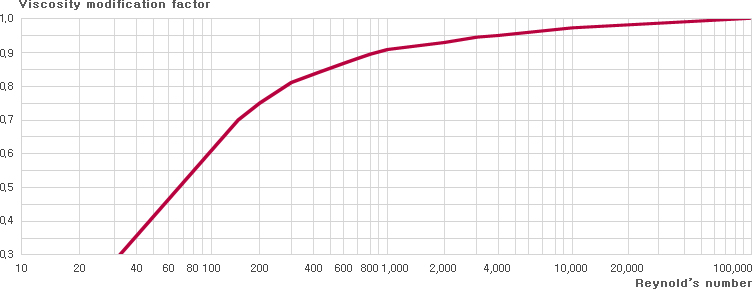

| Kv |

Viscosity Correction Factor Related to Reynolds Number (Re) If liquid viscosity is less than that of water at 20°C, kv = 1.0 (Refer to Capacity Correction Factor by Viscosity) |

|

| Re | Reynolds Number | |

| μ | Viscosity of Liquid | |

|

Differential Pressure Released through Rupture Disc Device  |

(bar a) |

| Pb | Back Pressure (Pressure on the Discharge Side) | (psia) |

| Name | Chemical Formula | Molecular Weight (M) | Adiabatic Index (k) |

|---|---|---|---|

| Acetylene | C2H2 | 26.04 | 1.26 |

| Air | 28.97 | 1.40 | |

| Ammonia | NH2 | 17.03 | 1.31 |

| Argon | Ar | 39.95 | 1.67 |

| Butadiene | C4H6 | 54.09 | 1.113 |

| Benzene | C6H6 | 78.12 | 1.12 |

| iso-Butane | iso-C4H10 or CH(CH3)3 | 58.12 | 1.10 |

| n-Butane | n-C4H10 | 58.12 | 1.09 |

| Carbon disulfide | CS2 | 76.14 | 1.21 |

| Carbon dioxide | CO2 | 44.01 | 1.29 |

| Carbon monoxide | CO | 28.01 | 1.40 |

| Chlorine | Cl2 | 70.91 | 1.36 |

| Cyclohexane | C6H12 | 84.16 | 1.09 |

| n-Decane | n-C10H22 | 142.29 | 1.03 |

| Ethane | C2H6 | 30.07 | 1.19 |

| Ethyl alcohol | C2H5OH or C2H6O | 46.07 | |

| Ethylene | C2H4 | 28.05 | 1.24 |

| Helium | He | 4.00 | 1.66 |

| n-Heptane | n-CH3(CH2)5CH3 or C7H16 | 100.21 | 1.05 |

| n-Hexane | n-C6H14 | 86.18 | 1.06 |

| Hydrogen chloride | HCl | 36.46 | 1.41 |

| Hydrogen | H2 | 2.02 | 1.41 |

| Hydrogen sulfide | H2S | 34.08 | 1.32 |

| Dichloro difluoro methane (R12) | CCl2F2 | 120.91 | 1.139 |

| Methane | CH4 | 16.04 | 1.31 |

| Methanol | CH3OH or CH4O | 32.04 | 1.20 |

| Methyl chloride | CH3Cl | 50.49 | 1.20 |

| Nitrogen | N2 | 28.01 | 1.40 |

| Nitrous oxide | N2O | 44.01 | 1.30 |

| n-Nonane | n-CH3(CH2)7CH3 or C9H20 | 128.26 | 1.04 |

| Oxygen | O2 | 32.00 | 1.40 |

| n-Pentane | n-CH3(CH2)3CH3 or C5H12 | 72.15 | 1.07 |

| n-Propane | n-CH3CH2CH3 or C3H8 | 44.10 | 1.13 |

| Water (Steam, Pure) | H2O | 18.02 | 1.133 |

| Sulfur dioxide | SO2 or O2S | 64.06 | 1.29 |

| Toluene | C6H5CH3 or C7H8 | 92.15 | 1.09 |

| Propylene | CH3CHCH2 or C3H6 | 42.08 | 1.15 |

| Octane | CH3(CH2)6CH3 or C8H18 | 114.00 | 1.05 |