Installation Guidelines

임직원 모두 하나 된 마음으로 신뢰가 기본인 회사를 만들어 갑니다.

You can prevent negligent accidents by thoroughly familiarizing yourself with the preparation steps for rupture disc installation (rupture disc inspection, holder inspection) and the installation instructions.

Handle the disc and nameplate with extreme care. Inspect the seat and dome-shaped portion of the disc for grooves, indentations, and scratches that could damage the disc, leading to leakage or reduced burst pressure. Never install a damaged disc. Installing a damaged disc can lead to premature rupture and prevent it from functioning as a safety device.

Inspect both surfaces of the holder where the disc is assembled. Dust, fine sand, and other debris can damage the rupture disc. These foreign substances and damage can affect the disc's operation, leading to disc damage or leakage. Clean the disc as thoroughly as possible. If there are grooves or scratches at the metal-to-metal contact area, lightly grind them with a whetstone before installation.

Holder size and grade must match those of the mating flange.

The rupture disc and holder must not be processed or modified in any way without the approval of FDC. If the user arbitrarily processes or modifies the product, the warrenty for the product will be void.

A rupture disc can be installed vertically or horizontally.

A rupture disc must be installed in the direction of fluid flow.

When handling a rupture disc, avoid contact with the parts intentionally processed for pressure setting (dome-forming part, scored processed part, slit processed part, etc.), and take special care to avoid damage by using the sheet part of the edge when holding the disc.

The rupture disc must be installed with the holder. If any damage is found on the disc, it must not be installed. (However, standalone installation is also possible depending on the model.)

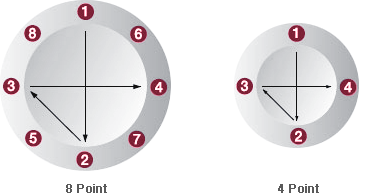

The surface of the both holder where the rupture disc will be assembled must be clean and free of any dust or defects. Also, all bolts must be tightened symmetrically and with the same force in the order shown in the figure below.

※ NOTE: Bolts must be tightened in this order with equal torque to prevent leaking.