Rupture Disc Applications

임직원 모두 하나 된 마음으로 신뢰가 기본인 회사를 만들어 갑니다.

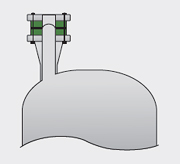

ASME CODE requires the specified rupture pressure to be set lower than the pressure vessel's MAWP when a rupture disc is used as a standalone safety device. The size should be large enough to prevent pressure from increasing by more than 10% of the MAWP of the pressure vessel or by 3 psi.

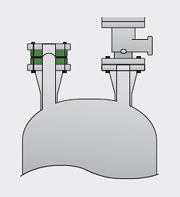

ASME CODE requires only one safety device to be set below MAWP when using multiple safety devices, and the other devices must not exceed 105% of the MAWP, except in the fire case. Also, the size should be enough to prevent the pressure vessel from rising by more than 16% or 4psi above the MAWP.

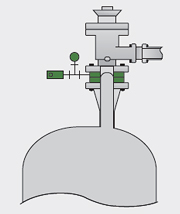

A rupture disc device can be installed between the safety velve and the process or on the outlet side of the safety valve if sufficient relief capacity is guaranteed. This prevents leakage and water leakage through the pressure safety valve and protects the safety valve from corrosion, etc. When installed on the inlet side of the safety valve, the actual relief capacity is recognized as 90% of the relief capacity imprinted on the safety valve (when tested under the same condition, the actual capacity is recognized). When used in combination with a safety valve, the rupture of the rupture disc must not disrupt the function of the safety valve, and sufficient space must be secured between the safety valve and the rupture disc with a device capable of detecting any pressure buildup (such as a pressure gauge, excess flow valve, or pressure switch) installed.

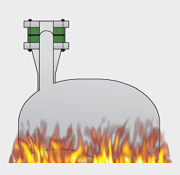

When additional hazards, such as fire or other unexpected external heat sources, may arise, an additional pressure relief device must be installed to protect against damage from excess pressure. In this case, the release capacity must be sufficient to prevent pressure increases exceeding 21% of the MAWP. The set pressure must not exceed 110% of the MAWP. When storing liquefied compressed gas at room temperature without a permanent supply connection, the pressure relief device, whose primary purpose is to protect the pressure vessel from fire or other unexpected external heat sources, must prevent pressure increases exceeding 20% of the MAWP.