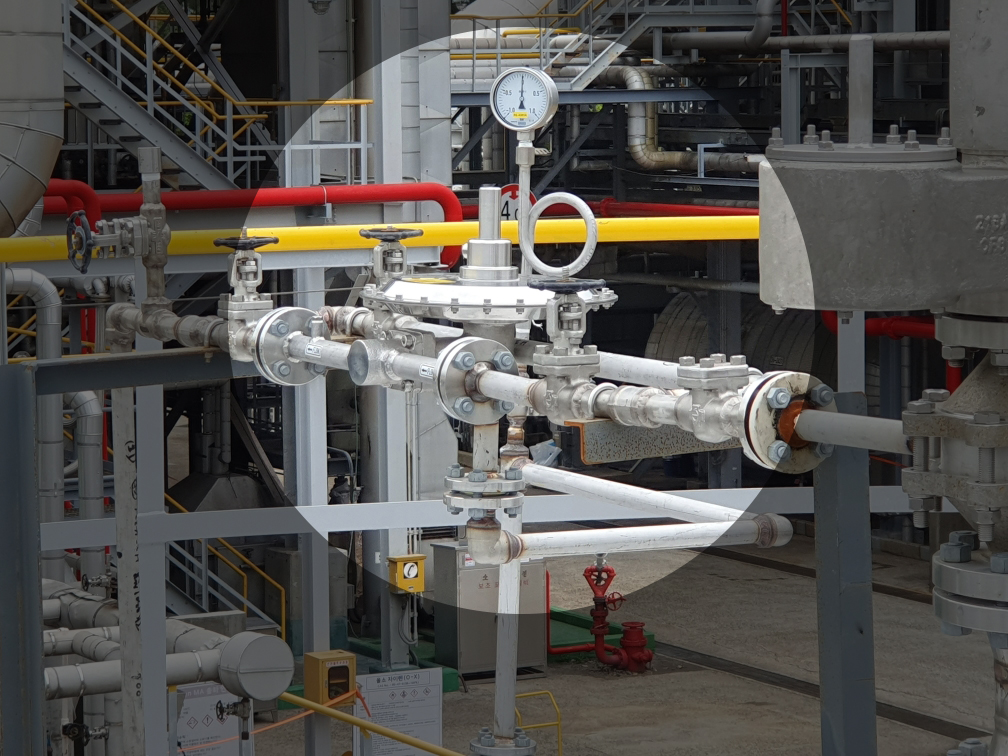

N₂ Blanketing System

A device that regulates the supply of N₂ gas, an inert gas, into the upper space of the tank to maintain a constant pressure state

A device that regulates the supply of N₂ gas, an inert gas, into the upper space of the tank to maintain a constant input state

Reduces evaporation loss of product by minimizing vapor formation within the tank

Eliminates the risk of explosion by suppressing the generation of harmful gases such as oxygen in the vapor space within the tank

Prevents product damage by blocking unnecessary moisture and air from entering from the outside

Prevents explosion by suppressing spark generation caused by static electricity

Improve product transfer rate by reducing product discharging time

Prevent deformation of the tank by suppressing vacuum transmission within the tank

Design |

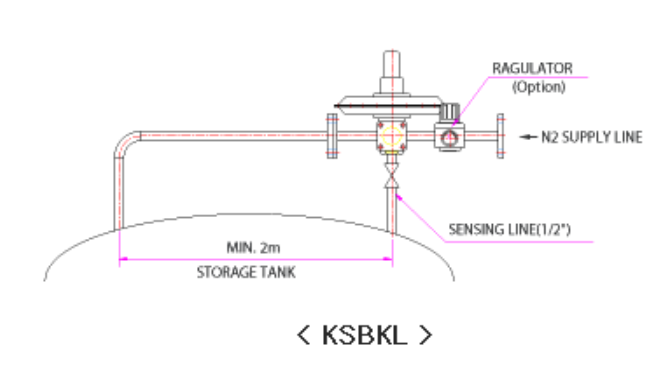

Single Operating Type |

|---|---|

Set Pressure |

12.5 ~ 8000 mmAq |

Size |

1/2”~2” |

Connection Type |

Standard Flange or Screwed Piping |

Available Service Phase |

Gas or vapor : Yes |

A device that regulates the supply of N₂ gas, an inert gas, into the upper space of the tank to maintain a constant input state

Reduces evaporation loss of product by minimizing vapor formation within the tank

Eliminates the risk of explosion by suppressing the generation of harmful gases such as oxygen in the vapor space within the tank

Prevents product damage by blocking unnecessary moisture and air from entering from the outside

Prevents explosion by suppressing spark generation caused by static electricity

Improve product transfer rate by reducing product discharging time

Prevent deformation of the tank by suppressing vacuum transmission within the tank

Design |

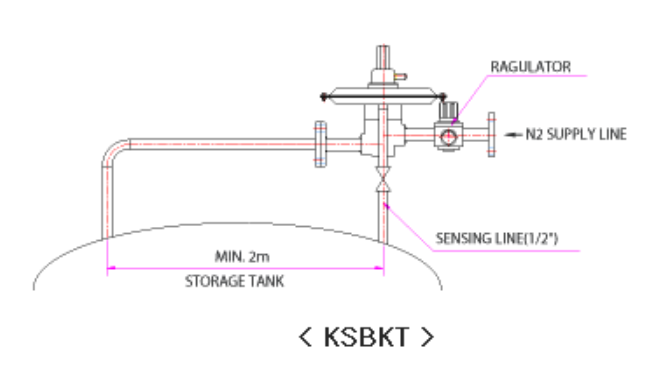

Pilot Operating Type |

|---|---|

Set Pressure |

20 ~ 8000 mmAq |

Size |

1/2”~2” |

Connection Type |

Standard Flange or Screwed Piping |

Available Service Phase |

Gas or vapor : Yes |

A device that supplies inert N₂ gas into the upper space of the tank while maintaining a constant input condition

Minimizes vapor formation inside the tank to reduce product evaporation loss

Suppresses the occurrence of harmful gas components such as oxygen in the vapor space of the tank to eliminate explosion factors

Blocks unnecessary moisture and air inflow from outside to prevent product damage

Prevents spark generation caused by static electricity to avoid explosions

Shortens product discharging time to improve transfer efficiency

Prevents vacuum formation inside the tank to avoid tank deformation

Design |

Pilot Operating Type |

|---|---|

Set pressure |

20 ~ 8000 mmAq |

Size |

1/2”~2” |

Connection type |

Standard Flange or Screwed Piping |

Available service phase |

Gas or vapor : Yes |