Rupture Disc

A non-mechanical safety device to release overpressure exceeding the limit pressure in the pressure system.

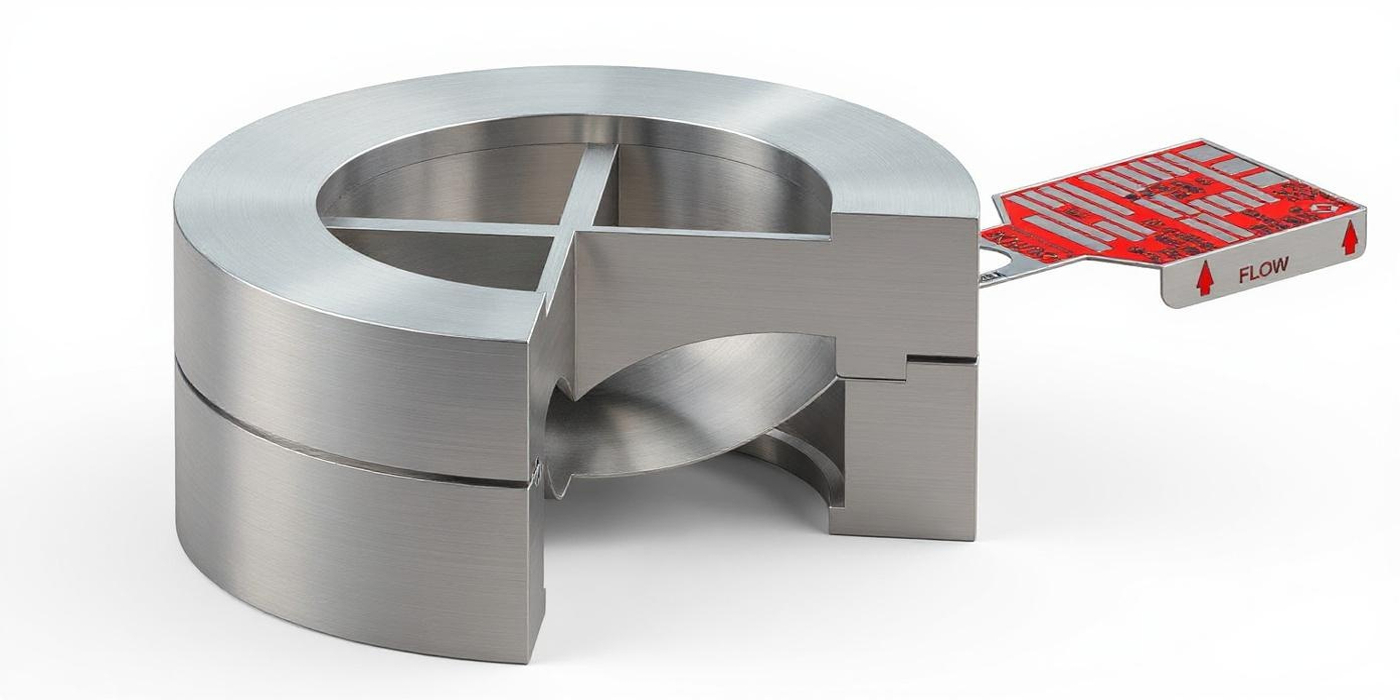

Reverse Dome Knife Type

Install on the FDC standard holder to use

Inverted structure ruptured by the knife blade attached to the upper holder as the dome is inverted

High safety and strong corrosion resistance

Advantageous under back pressure, vacuum, pulsation conditions - No vacuum support required

Wide range of operating temperature conditions

High operating cost

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

Max. 593℃ |

Vacuum support required |

No |

Spark |

Yes |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase | Gas or vapor : Yes |

|---|---|

Liquid : No |

0.3~150kg/㎠ [1/2"~48"(15A~1,200A)]

Inquire separately for other specifications

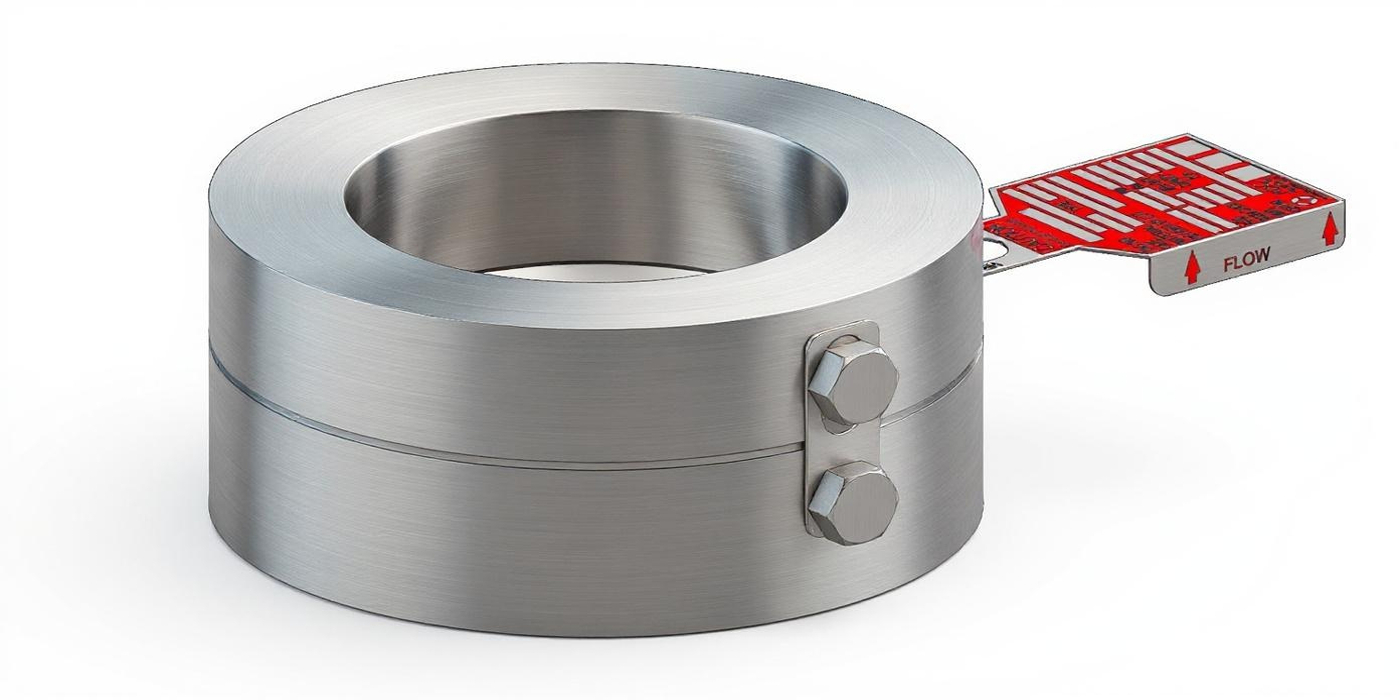

Reverse Dome Shear Type

Installed and used in FDC standard holder

Disc and knife integrated

Shear-actuated structure ruptured by the knife ring attached to the upper disc as the dome is inverted

High safety and strong corrosion resistance

Advantageous under back pressure, vacuum, pulsation conditions – No vacuum support required

Wide operating temperature range

High operating ratio

Easier handling compared to KSRR

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

-200℃ ~ 600℃ |

Vacuum support required |

No |

Spark |

No |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase |

Gas or vapor : Yes |

Liquid : Yes |

0.35~30kg/㎠ [1/2"~24"(15A~600A)]

Other specifications available upon request

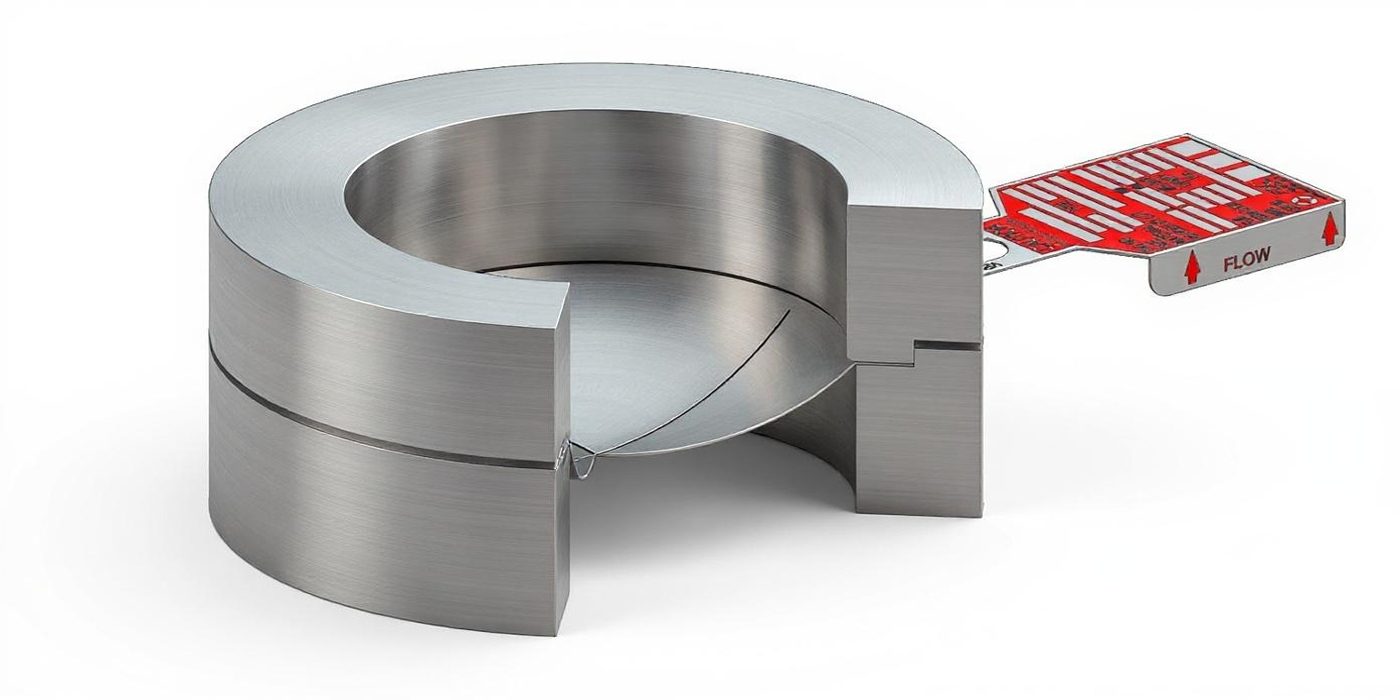

Reverse Dome Buckling Type

Install on the flange without a separate holder to use

Shear-actuated structure ruptured by the knife shape of the control disc as the dome shape of the rupture disc is inverted

Can be used for all fluids such as liquid, gas, steam, vapor, sludge, and resin

High safety and strong corrosion resistance

Wide range of operating temperature conditions

High operating cost

Easy to handle with high resistance against external impact

Precise rupture performance and excellent reliability

Patented product

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

Max. 593℃ |

Vacuum support required |

No |

Spark |

No |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase |

Gas or vapor : Yes |

Liquid : Yes |

0.1~100kg/㎠ [1/2"~36"(15A~900A)]

Other specifications available upon request

Reverse Dome Scored Type

Install on the FDC standard holder to use

An angle-activated flip/tear structure that reverses along a precisely processed scored line

Mainly applied to medium and high pressure

High safety, high corrosion resistance

Advantageous under back pressure, vacuum, pulsation conditions – No vacuum support required

Wide operating temperature range

High operating ratio

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

Max. 593℃ |

Vacuum support required |

No |

Spark |

No |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase |

Gas or vapor : Yes |

Liquid : Yes |

1.5~150kg/㎠ [1/2"~24"(15A~600A)]

Other specifications available upon request

_01.jpg)

_02.jpg)

_03.jpg)

Reverse Dome Scored Type (Figure C)

An angle-activated flip/tear structure that reverses along a precisely machined scored line, C-shaped

Mainly applied to medium pressures

High safety and strong corrosion resistance

Advantageous under back pressure, vacuum, pulsation conditions – No vacuum support required

Wide operating temperature range

High operating ratio

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

Max. 593℃ |

Vacuum support required |

No |

Spark |

No |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase |

Gas or vapor : Yes |

Liquid : Yes |

0.3~150kg/㎠ [1/2"~32"(15A~800A)]

Other specifications available upon request

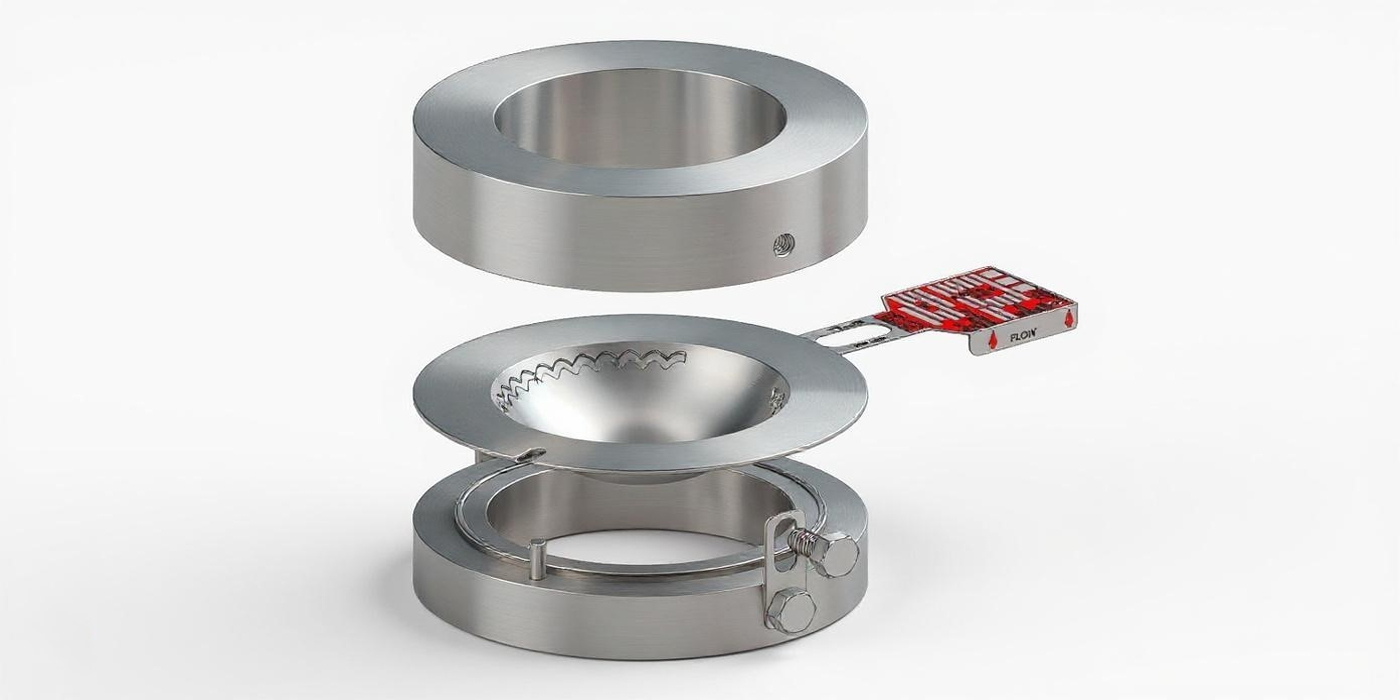

Reverse Dome Buckling Knife Type

Installed and used in FDC standard holder

Consists of a control disc and a seal disc

Shear-actuated structure ruptured by the knife shape of the control disc as the dome shape of the rupture disc is inverted

Can be used for all fluids such as liquid, gas, steam, vapor, sludge, and resin

High safety and strong corrosion resistance

Advantageous under back pressure, vacuum, pulsation conditions – No vacuum support required

Wide operating temperature range

High operating ratio

Resistant to external impact, easy handling

Precise rupture performance and excellent reliability

Patented product

Material |

Stainless Steel, Hastelloy, Monel, Nickel, Titanium, Tantalum, Duplex, Special Alloy, Aluminum, Etc. |

Temperature |

Max. 593℃ |

Vacuum support required |

No |

Spark |

No |

Fragment |

No |

Max. operating ratio |

90 % |

Available service phase |

Gas or vapor : Yes |

Liquid : Yes |

0.1~100kg/㎠ [1/2"~36"(15A~900A)]

Other specifications available upon request